Nema 14 (35mm) hybrid ball screw stepper motor 1.8° Step Angle Boltahe 1.4 / 2.9V Current 1.5A, 4 na Lead Wires

Nema 14 (35mm) hybrid ball screw stepper motor 1.8° Step Angle Boltahe 1.4 / 2.9V Current 1.5A, 4 na Lead Wires

Nema 14 (35mm) hybrid stepper motor, bipolar, 4-lead, ball screw, mababang ingay, mahabang buhay, mataas na pagganap, sertipikado ng CE at RoHS.

Paglalarawan

| Pangalan ng Produkto | 35mm hybrid ball screw stepper motor |

| Modelo | VSM35BSHSM |

| Uri | mga hybrid na stepper motor |

| Anggulo ng Hakbang | 1.8° |

| Boltahe (V) | 1.4 / 2.9 |

| Kasalukuyang (A) | 1.5 |

| Resistance (Ohms) | 0.95 / 1.9 |

| Induktans (mH) | 1.5 / 2.3 |

| Mga Kable ng Tingga | 4 |

| Haba ng Motor (mm) | 34 / 45 |

| Temperatura ng Nakapaligid | -20℃ ~ +50℃ |

| Pagtaas ng Temperatura | Pinakamataas na 80K |

| Lakas ng Dielektriko | Pinakamataas na 1mA @ 500V, 1KHz, 1 Segundo |

| Paglaban sa Insulasyon | 100MΩ Min. @500Vdc |

Mga Sertipikasyon

Mga Parameter na Elektrikal:

| Laki ng Motor | Boltahe/ Yugto (V) | Kasalukuyan/ Yugto (A) | Paglaban/ Yugto (Ω) | Induktans/ Yugto (mH) | Bilang ng Mga Kable ng Tingga | Inersia ng Rotor (g.cm2) | Timbang ng Motor (g) | Haba ng Motor L (milimetro) |

| 35 | 1.4 | 1.5 | 0.95 | 1.4 | 4 | 20 | 190 | 34 |

| 35 | 2.9 | 1.5 | 1.9 | 3.2 | 4 | 30 | 230 | 47 |

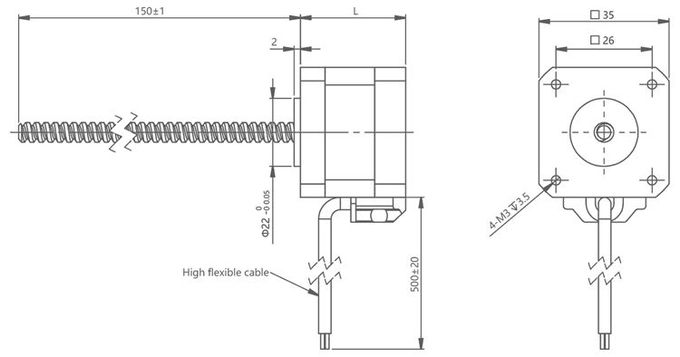

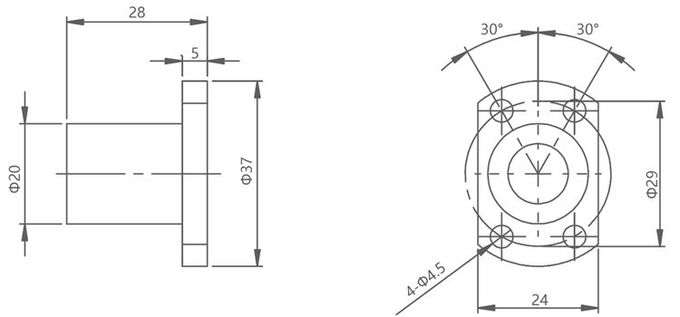

Guhit ng balangkas ng karaniwang panlabas na motor ng VSM35BSHSM

Mga Tala:

Maaaring ipasadya ang haba ng tornilyo na tingga

Ang customized machining ay maaaring gamitin sa dulo ng lead screw

Mangyaring makipag-ugnayan sa amin para sa higit pang mga detalye ng ball screw.

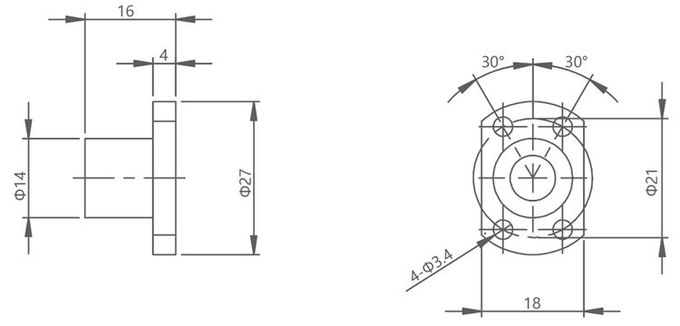

Guhit na balangkas para sa VSM35BSHSMBallan nut 0801 o 0802

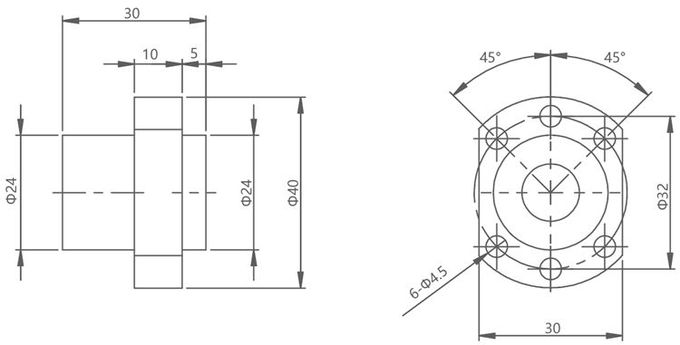

Pagguhit ng balangkas ng VSM35BSHSMBallan 1202

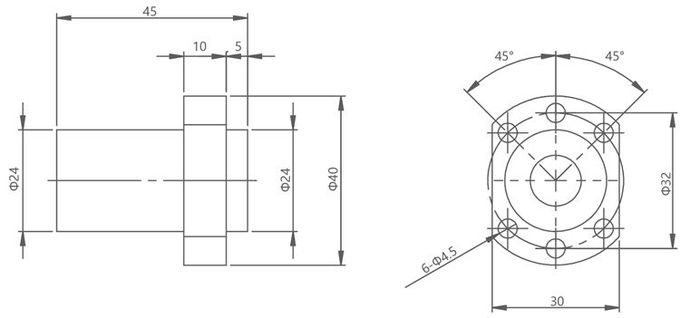

Guhit na balangkas ng VSM35BSHSMBallanong nut 1205:

Pagguhit ng balangkas ng VSM35BSHSMBallan na nut 1210

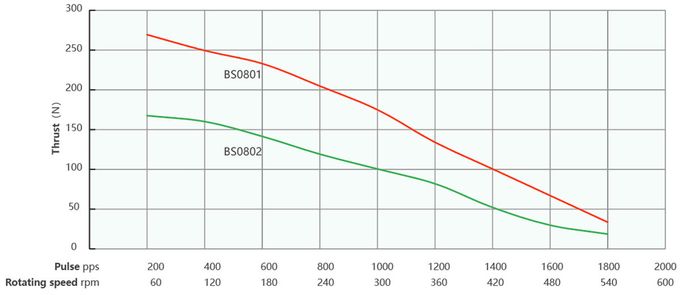

Kurba ng bilis at tulak

35 serye 34mm na haba ng motor na bipolar Chopper drive

100% dalas ng pulso ng kasalukuyang at kurba ng tulak

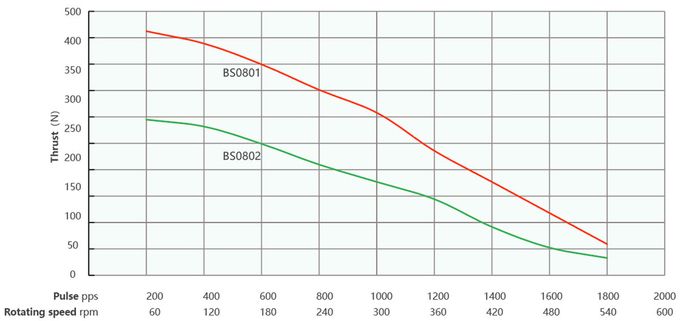

35 serye 47mm na haba ng motor na bipolar Chopper drive

100% dalas ng pulso ng kasalukuyang at kurba ng tulak

| Tingga (mm) | Linya ng bilis (mm/s) | |||||||||

| 1 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| 2 | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 |

| 5 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 |

| 10 | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 |

Kondisyon ng pagsubok:Chopper drive, walang ramping, kalahating micro-stepping, boltahe ng drive 24V

Mga lugar ng aplikasyon:

Awtomasyon sa Industriya:Ang mga 35mm hybrid ball screw stepper motor ay malawakang ginagamit sa mga aplikasyon ng industrial automation. Maaari itong gamitin sa mga automated assembly lines, conveyor system, robotic arm, at iba pang makinarya na nangangailangan ng tumpak na pagpoposisyon at maaasahang kontrol sa paggalaw.

Makinarya ng CNC:Ang mga makinang Computer Numerical Control (CNC) ay gumagamit ng 35mm hybrid ball screw stepper motors para sa kanilang mataas na katumpakan at katumpakan. Ang mga motor na ito ay gumaganap ng mahalagang papel sa pagkontrol sa paggalaw ng mga cutting tool, na tinitiyak ang tumpak na mga hiwa at pare-parehong resulta sa iba't ibang operasyon sa machining.

3D Printing:Ang mga 35mm hybrid ball screw stepper motor ay angkop para sa mga 3D printer, kung saan nagbibigay ang mga ito ng kinakailangang kontrol para sa paggalaw ng print head o build platform. Ang kanilang mataas na torque at katumpakan ay nakakatulong sa tumpak na pagpapatong-patong at masalimuot na mga detalye sa mga 3D-printed na bagay.

Mga Kagamitang Medikal:Sa larangan ng medisina, ang 35mm hybrid ball screw stepper motors ay ginagamit sa iba't ibang kagamitang medikal, kabilang ang mga diagnostic instrument, surgical robot, automated drug dispenser, at prosthetic device. Ang mga motor na ito ay nag-aalok ng kinakailangang katumpakan at pagiging maaasahan para sa mga kritikal na medikal na pamamaraan at kagamitan.

Kagamitan sa Laboratoryo:Ang mga instrumento sa laboratoryo at mga aparatong analitikal ay kadalasang gumagamit ng 35mm hybrid ball screw stepper motors para sa tumpak na pagpoposisyon at pagkontrol ng galaw. Matatagpuan ang mga ito sa mga robot sa laboratoryo, mga sistema ng paghawak ng likido, mga mekanismo ng paghawak ng sample, at iba pang kagamitan na nangangailangan ng tumpak at paulit-ulit na mga galaw.

Mga Sistemang Optikal:Ang mga aplikasyon sa optika at photonics, tulad ng mga laser system, microscopy, spectroscopy, at optical alignment system, ay nakikinabang mula sa mataas na katumpakan at katatagan na ibinibigay ng 35mm hybrid ball screw stepper motors. Ang mga motor na ito ay nagbibigay-daan sa tumpak na kontrol ng mga optical component, na tinitiyak ang tumpak na pagpoposisyon at pagkakahanay ng beam.

Pagbabalot at Paglalagay ng Label:Ang mga makinang pang-pambalot at pang-label ay umaasa sa tumpak na pagkontrol ng galaw upang matiyak ang tumpak na pagpoposisyon at paglalagay ng mga label, materyales sa pagbabalot, at mga pansara. Ang mataas na katumpakan at kakayahang maulit ng 35mm hybrid ball screw stepper motor ay ginagawa silang angkop para sa mga ganitong aplikasyon, na nagpapabuti sa kahusayan ng pagbabalot at kalidad ng produkto.

Kagamitan sa Semikonduktor:Sa industriya ng semiconductor, ang 35mm hybrid ball screw stepper motors ay ginagamit sa iba't ibang kagamitan, kabilang ang mga wafer handling system, mga inspection tool, at mga lithography machine. Ang mga motor na ito ay nakakatulong sa tumpak na paggalaw at pagkakahanay na kinakailangan para sa mga proseso ng paggawa ng semiconductor.

Kalamangan

Mataas na Katumpakan sa Pagpoposisyon:Ang 35mm hybrid ball screw stepper motors ay nag-aalok ng mataas na katumpakan sa pagpoposisyon. Binabawasan ng ball screw transmission system ang backlash at nagbibigay ng mahusay na repeatability, na nagbibigay-daan sa motor na tumpak na maabot ang ninanais na posisyon. Ang katumpakan na ito ay mahalaga sa mga aplikasyon kung saan kritikal ang tumpak na pagpoposisyon.

Napakahusay na Output ng Torque:Ang mga motor na ito ay nagbibigay ng mataas na torque output, na nagpapahintulot sa kanila na magmaneho ng mas malalaking load o mapanatili ang matatag na paggalaw kahit na may iba't ibang load. Mahusay na kino-convert ng mekanismo ng ball screw ang rotary motion ng motor tungo sa linear motion, na nagreresulta sa epektibong torque transmission.

Mataas na Kahusayan:Kilala ang mga stepper motor sa kanilang kakayahang tumugon at kahusayan. Mabilis silang tumugon sa mga signal ng kontrol at nakakamit ng tumpak na pagpoposisyon at pagkontrol ng galaw nang hindi nangangailangan ng karagdagang mga sensor o feedback system. Ang kahusayang ito ay nakakatulong sa pangkalahatang pagganap ng motor at ng sistemang kinabibilangan nito.

Mababang Panginginig ng boses at Ingay:Ang mga 35mm hybrid ball screw stepper motor ay karaniwang nagpapakita ng mababang antas ng vibration at ingay habang ginagamit. Ang katangiang ito ay partikular na mahalaga sa mga aplikasyon kung saan ninanais ang mababang antas ng ingay o kung saan ang vibration ay maaaring makaapekto sa pagganap o katumpakan ng sistema.

Kahusayan at Katatagan:Ang mga motor na ito ay karaniwang kilala sa kanilang mataas na pagiging maaasahan at tibay. Ang sistema ng transmisyon ng ball screw ay nagbibigay ng mahusay na distribusyon ng karga at pinahabang buhay ng serbisyo, na nagpapahintulot sa motor na mapanatili ang katatagan at pagiging maaasahan sa panahon ng matagalang operasyon at paulit-ulit na paggamit.

Sukat na Kompakto:Dahil sa compact form factor nito, ang 35mm hybrid ball screw stepper motors ay madaling maisama sa mga aplikasyon na may limitadong espasyo. Nag-aalok ang mga ito ng mataas na performance at tumpak na kontrol habang kumukuha ng mas maliit na espasyo, kaya angkop ang mga ito para sa mga aplikasyon kung saan limitado ang laki.

Madaling Kontrol at Operasyon:Nag-aalok ang mga stepper motor ng simpleng control interface, na nagbibigay-daan para sa direktang operasyon at integrasyon sa iba't ibang sistema ng kontrol. Madali itong makontrol gamit ang mga pulse at direction signal o mas advanced na control algorithm, depende sa mga partikular na kinakailangan sa aplikasyon.

Mga Kinakailangan sa Pagpili ng Motor:

►Direksyon ng paggalaw/pagkakabit

►Mga Kinakailangan sa Pagkarga

►Mga Kinakailangan sa Stroke

►Mga kinakailangan sa pagtatapos ng pagma-machining

►Mga Kinakailangan sa Katumpakan

►Mga Kinakailangan sa Feedback ng Encoder

►Mga Kinakailangan sa Manu-manong Pagsasaayos

►Mga Pangangailangan sa Kapaligiran

Pagawaan ng produksyon